Hi, Fellow Tobaccophiles,

As many of you know, I was just nuked, back to the stone-age. Ed Sallee, of Waxing Moon Wood, bombed me an absolutely beautiful, 50ct humidor.

Our Subject:

So now, guess what? You all get to go through the seasoning process with me.

First, I tested the seal... well, sort of. When I first opened the packaging and went to open the humi, it took a LOT of effort. When I spoke with Ed, he said that the only reason he'd put the latch on it, was because he himself had had difficulty opening the box. This is a very good thing.

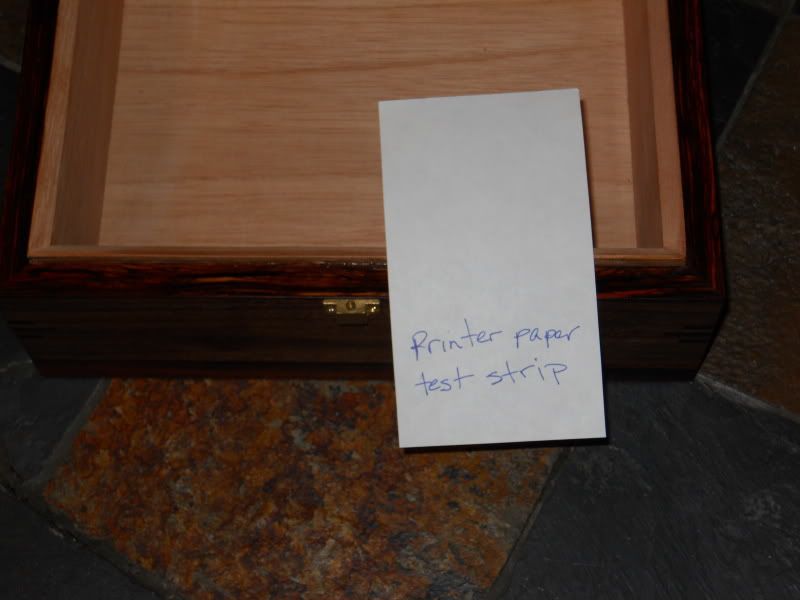

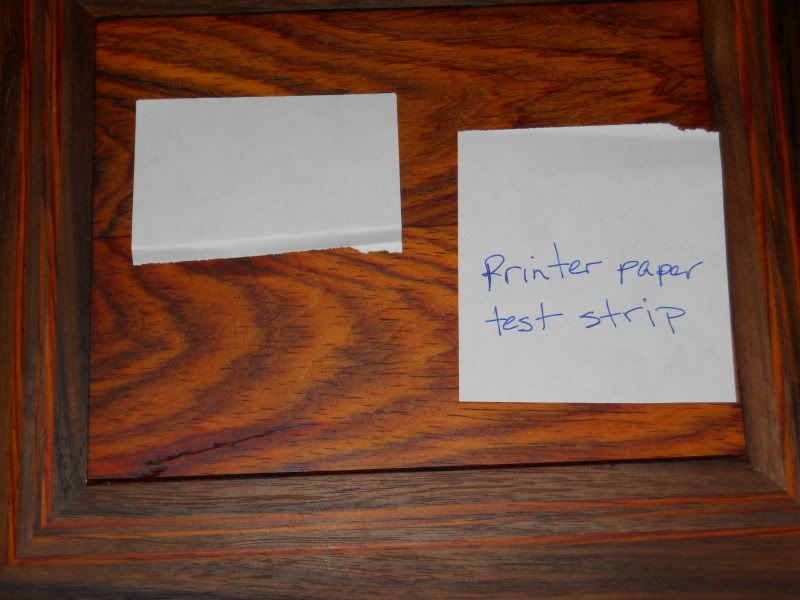

For the sake of this tutorial, I did a paper strip test (akin to the dollar bill test, but more precise).

Here, you can see the results:

The seal is so tight that the test paper was no match. I tried hard to pull it out, but there was no give. The test resulted in catastrophic failure of the paper. Another reason not to use a dollar bill on a top-quality humidor I omitted the flashlight test and the whoosh test was pointless, since the lid won't close without a little down-pressure. Did I mention that this seal is t-i-g-h-t, tight? For others, using this as a reference guide, definitely do all the tests, until you are absolutely certain of your seal's integrity!

Next, I took a pre-doing-anything, hygrometer reading. This revealed an RH of 54%. Ed, was kind enough to ship it with three water pillows inside, which, no doubt, helped it a little from what the ambient humidity in his workshop must be.

Now that we've tested both seal and original RH, it's time to start seasoning.

Using a new, straight out of the packaging, sponge, I dowse it with distilled water and place it on a saucer. I use Corell, but almost any saucer will work

I placed the saucer and sponge in the humidor, with one of my calibrated hygrometers, at 1600hrs. First check was at 2300hrs, which rendered an RH of 64%. This doesn't mean that the wood's at 64%, merely that there is more moisture in the air inside the humidor. We're headed in the right direction!

Tomorrow afternoon, I will open and check again. I expect to see a reading of around ~70%, at which point, I will install a tube of DRY!, 70% Heartfelt beads. The reason I do this is because I don't want to spike the humidity (more coming on this). I install the beads as a buffer, to keep the moisture in the wood from climbing above 70%. Otherwise, I cost myself several days of bringing it back down. I will then leave the beads in there until I can clearly see some of them turning clear (hydrated). At this point, it will be time to install cigars.

I will have to play some of this "by ear", since Ed uses thicker cedar stock than any other humidor maker of which I am aware. I will also have to determine the disparate absorption rates of cedar vs beads. If I put the beads in too soon, the beads will over-charge, before the wood is fully seasoned. The flip-side is the risk of over-seasoning the wood. The RH of the air inside the box, is no indicator of the condition of the wood. This is where experience, science and plain old guess work come in.

Stay tuned!

Well, Guys, things are going along swimmingly and precisely according to schedule!

I opened the humidor again, at 1335hrs (day two) and, lo and behold, we have a nice reading of 70%:

When I get home from my errands this evening, I will check again. I expect to be slightly over 70% by then and it will be time for the HF tube.

Just a note, on hygrometer placement:

It is absolutely essential, that for all readings taken during the initial testing and seasoning phases, you place the calibrated hygrometer on the floor of the humidor, NOT, the lid! The reason for this is that humid air rises. The floor of the humidor will be the last to season properly, so it's critical that all readings are taken with the calibrated hygrometer on the floor!

Alrighty! At 2300hrs, which is precisely 24hrs since placing the soaked sponge of distilled water inside, we've hit 79%. I know what you're thinking! "Haha, silly HNT went'n spiked his humidity after all!"

Not so, say I. Part of the guess work is involved in the fact that we're dealing with a lot of cedro here. We've managed to get the air inside the box up to 79%, but the wood is actually far behind it. Right now, my best guess is that the wood surface is around 70%, but the deeper/further outwards from the surface you go, the dryer things are.

So, now to install the beads. As I said above, the beads will help to stabilize the air inside the box, yet allow the moisture already in the wood surface to continue to travel outwards and stabilize the wood. Which is, after all, our common goal in this process.

This phase is called, "hydration". The Spanish cedar's condition, species (there are seven), growth climate, cut, age, pore structure, grain density and thickness (whew), all factor into determining how long the hydration phase of seasoning will take. Here, 24hrs seems to have us on target. In some cases, this phase (assuming a tight seal) can take 2-3 days. Also, the size of the box, eg, volume, can also play a big role. More volume equals more air and wood, which all have to become moistened.

We are now embarking upon (I hope) the "stabilization" phase. Usually, this is the one, which requires the most patience. The temptation to, "just have a little peek", can be overwhelming. Don't do it! Your distilled water is in two states; liquid (inside the wood) and gas (in the air inside the box). Any disturbance of the gas could cost you 10% RH. You need this water gas to enter the wood and return to liquid if you ever hope to achieve that perfectly seasoned humidor.

To be clear, the whole idea of optimum stabilization is about being best prepared to do battle against the many variables your system will encounter in the future. Most of us live in what's known as, the "temperate zone". In North America, this runs from roughly Anchorage, AK, to the southern tip of the Baja Peninsula. Farther east, from central Norway, to MacKay, Queensland, Australia. In this zone, we don't typically need to remove moisture, but rather add it. We need to get the Spanish cedar (our largest humidification medium) as completely seasoned to our desired humidity as possible. Only then, can we use our secondary media (beads, credo, whatever), to simply regulate the RH of the air inside.

Overly dry, overly moist cigars, the humidor's seal and how often we open the box, will then determine how much secondary media we require.

Just a note on ambient temperature: At higher temps, water turns to gas at a much faster rate. That means, if your house is 75*F, it's going to take a lot longer to convert water gas back into liquid. This is one of the reasons that the impatient recommend wiping down the wood. Sure, it goes faster, but the risk of warping isn't worth the time savings. At lower temps, you turn liquid to gas a lot slower. This means that it will take a lot more water and exposed surface area in order to exchange enough to get the wood moistened quickly. I'd much rather add more water to the sponge and let the wood do it's thing, than to force the wood to drink.

Now that we're looking towards stabilization, I won't open the box again, for another 24hrs.

Stay tuned.

User Tag List

Results 1 to 4 of 4

-

02-24-2015, 03:40 PM #1The Walrus

- First Name

- Don

- Join Date

- Feb 2015

- Location

- The Old Dominion

- Posts

- 1,787

- Ring Gauge

- 745

- Mentioned

- 155 Post(s)

- Tagged

- 0 Thread(s)

How Herf N Turf Seasons a New Humidor

Debt is the weapon used to conquer and enslave societies and interest is it's ammunition.

-

Post Thanks / Like - 3 Thanks, 1 Likes

BlueDevil07 liked this post

BlueDevil07 liked this post

-

02-24-2015, 03:41 PM #2The Walrus

- First Name

- Don

- Join Date

- Feb 2015

- Location

- The Old Dominion

- Posts

- 1,787

- Ring Gauge

- 745

- Mentioned

- 155 Post(s)

- Tagged

- 0 Thread(s)

Update:

Last night when I checked the humidor, at 2300, It was reading 75%. The beads didn't appear to be putting up much of a fight, so I removed the sponge. Today, at 1100, I opened it up and it was still at 74%.

Time for a little impatience.

I opened the box and removed the hygrometer. Leaving the box open, I set the hygro on the table. I actually fanned the box to clear all humidity and waited for the hygro to drop below 70%, before re-installing it and closing the box back up.

After letting it sit for an hour, this is what I saw:

Wa-lah! We are now well into the stabilization phase, with a nice reading of 70% and some adequately hydrated beads. Yipee!

I will re-open tonight at about 2300 and if we're still near 70%, we might be installing sticks sometime tomorrow!

Stay tuned.Debt is the weapon used to conquer and enslave societies and interest is it's ammunition.

-

Post Thanks / Like - 2 Thanks, 1 Likes

-

02-24-2015, 03:46 PM #3The Walrus

- First Name

- Don

- Join Date

- Feb 2015

- Location

- The Old Dominion

- Posts

- 1,787

- Ring Gauge

- 745

- Mentioned

- 155 Post(s)

- Tagged

- 0 Thread(s)

Final Chapter:

Well, as predicted, when I checked the box again tonight, we were right where we'd predicted.

A solid reading of 69% tells us our labors are done and it's time to install sticks. Total seasoning time: 3days, 10.5hrs. Not bad.

Someone asked what I was going to fill it with. Well, Ed decided that when he sent me the humidor. Along with this beautiful box, he also sent me an Arturo Fuente Anejo Xtra Viejo 55. So, the Fuente family has moved into my "Coco-Nut" Waxing Moon humidor (Black Walnut and Cocobolo woods).

So, time to close this up and grab something to smoke!

Thanks for watching!Debt is the weapon used to conquer and enslave societies and interest is it's ammunition.

-

Post Thanks / Like - 6 Thanks, 4 Likes

-

03-18-2015, 12:51 PM #4The Walrus

- First Name

- Don

- Join Date

- Feb 2015

- Location

- The Old Dominion

- Posts

- 1,787

- Ring Gauge

- 745

- Mentioned

- 155 Post(s)

- Tagged

- 0 Thread(s)

1) The Air - in virtually all cases, except a new box of cigars, air is what you have in greatest abundance. It's also the main thing we can manipulate. Air is the guard at the gate to the castle of the perfect cigar.

2) The Cigar - assuming we keep our humidors mostly filled, the tobacco inside is the second-most impactful humidification device. Tobacco is far more porous and elastic than wood, so it can absorb and desorb vast amounts of water relatively quickly.

3) The Wood - that Spanish cedar lining is a wonderful thing. It looks terrific, it emits a pleasant aroma and, over long periods, introduces it to the cigar, it's highly porous for a hard wood, so can hold a tremendous amount of water and it sports a native moisture content of ~74%, so it does all this pretty darn close to where we want to store our cigars.

4) Your chosen device - This of course means your beads, Boveda, Credo, Oasis... whatever, which manipulates the condition of the air, in order to regulate the amount of moisture made available to the tobacco and wood.

Think of everything as a SYSTEM; "head bone's connected to the thigh bone"... Everything must work in harmony in order to achieve the end goal. What we need to do then is to first address the air, then the wood. We want to get as much water vapor into the air as possible, so it can be delivered to the wood to drink. Inside the wood, the gas is reverted to a liquid, which then collects on the surface of the wood to be returned into gas and then back into liquid inside the cigar, whew...Debt is the weapon used to conquer and enslave societies and interest is it's ammunition.

-

Post Thanks / Like - 3 Thanks, 1 Likes